Global Runway Reporter

Global Runway Reporter is a modern software cluster designed for making runway inspection and maintenance effortless and efficient and also Global Reporting Format (ICAO GRF) standardized. Get alerted when inspection is timely. Report contaminants easily directly from the inspection vehicle with Mobile software. Explore with limitless visual analytics. Customize analyzing tools and perform analyses in just a few clicks. From the biggest airports to the smallest ones uses Global Runway Reporter to report runway conditions and generate consistent SNOWTAM syntax.

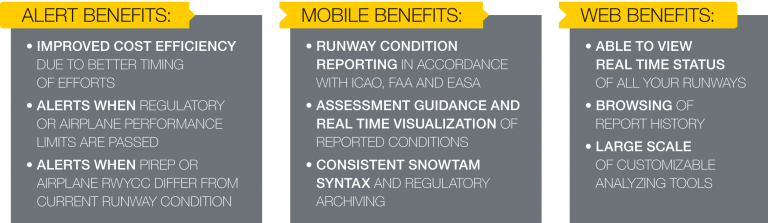

The four modules cover the whole process of Runway Reporting and makes it simple and safe. Alerter improves cost efficiency due to better timing of efforts and gives alerts when PIREP or aeroplane RWYCC differ current runway condition. Mobile software gives guidance for the user for assessment and visualises reported conditions on real time. Web software allows history browsing and running unlimited analysis from the database.

Global Runway Reporter

– To who

ICAO (International Civil Aviation Organization) has put lot of effort to build up a harmonized reporting system called Global Reporting Format (GRF). The purpose of this is that no matter where the pilot is landing, he or she is getting the runway report in same format and in a way that the reported condition is the same in all airports. This new format replaces all existing formats in November 2020. All airports should report runway conditions according to this Global Reporting Format by then. So basically all airports should report runway conditions and with Global Runway Reporter software this can be easily done in a way that it always follows ICAO standards.

Runway inspectors

Mobile software working inside the inspection vehicle is a modern tool for runway inspectors to report runway conditions. It´s based to work on touch screen tablet computer. To utilize the real time status of runways, WiFi or mobile network connection is a great benefit. This way the reporting is instant from the inspection vehicle. Mobile software sends information to server which generates SNOWTAM syntax according to ICAO Global Reporting Format (GRF). Server forwards the data to relevant parties such as Eurocontrol, tower (ATC), Briefing (C) and others based on customers needs. The outputs can be customized to match the needs.

Runway maintenance group

Alert module is designed to help maintenance people to decrease the workload for monitoring. We can connect to your existing sensors in the runway and monitor weather forecasts. Also we are able to get feedback from Airport Traffic Control (ATC) when pilot reports (AIREP) differs from the Runway condition code (RWYCC) given by the inspector. This way we can alert the inspectors to make new assessment when needed. This takes care of the regulatory side of ICAO/FAA/EASA/etc. when it´s mandatory to make new assessment and also other milestones when new runway report would increase safety. Sometimes it´s also mandatory to go and actually clean and treat the runway and instead of alerting to make new report we can alert to make new maintenance action. This increases the correct timing of runway maintenance which generates big savings for less usage of machines and chemicals.

Others

The runway condition data can be utilized in all ways we can imagine. Many times there is need to have screen in Air Traffic Control (ATC) to see status of the runways. Global Runway Reporter can generate customized screens to support this need where relevant persons can see runway status with visualized outputs in clear and quick manner. The screens can be taken to briefing as well where pilots plans the flight and take-off parameters. Runway condition report is used for take-off as well so this is very important information to flight crew. Sometimes there is need to do analysis of the runway condition data and with Web-module that is made easy. We can customize analysis tools based to customers needs and run almost unlimited amount of reports of the data. With combined runway contaminant data with friction tester data there is possibility to create safely analysis to combine friction values to reported runway conditions. This helps to generate supporting tool for inspectors where they can back up their RWYCC decision making with friction testing results.

Global Runway Reporter – Suitable for all airports

Global Runway Reporter software cluster consists four modules; Alert, Mobile, Web and Trainer. Each of these modules can be selected individually based on customers needs. Customization is possible in other ways as well. With this modular approach we are able to have exactly the wanted outcome for each customer without big customization cost. The three modules covers the needs for all aspects of runway condition reporting, monitoring and training.

The new RCAM runway reporting table is designed for landing airplanes. The importance of landing safety can´t be underestimated but this generates other issue which is not discussed because of lack of understanding of this topic and that is the takeoff. When using the the same Runway Condition Code for landing and takeoff can be very dangerous in certain situations. And those situations occurs when we report slippery conditions which generates low Runway Condition Code but are still thick which also generate drag when airplane is taking off. This can lead to catastrophic overruns if for example engine breaks during acceleration.

There are multiple situations when the information generated by the RCAM table is not enough for safe takeoff. In our Global Runway Reporter software there is an in-built feature which takes care of this issue. Thanks for our long history of providing airplane performance software we have the understanding needed to tackle this topic. We report runway conditions in a way that we are able to calculate the most significant contaminant for takeoff. This increases safety when we don´t compromise takeoff safety when reporting landing conditions. Airplane companies are very happy with this when our provided information makes their decision making process easier when calculating the takeoff performance parameters.

- Alert benefits

- Mobile benefits

- Web benefits

- Help decision making with friction tester

- Improve accuracy with contaminant sensors

– Runway condition monitoring and -forecasting

– Alerts when PIREPs differ from current runway RWYCC

– Alerts when aeroplane RWYCC differs from current RWYCC

– Alerts when runway freezing becomes probable

– Better timing of maintenance and assessments efforts

– Saves overall efforts

– Reportable areas and contaminant observation and -input

– Friction measuring integration

– Real time runway visualization of reported conditions during input

– RWYCC assessment (RCAM, friction, reportable)

– SNOWTAM message creation and publishing

– Report data visualiation for ATC and briefing

– Real time status of all your airports and runways

– Browsing of runway data history

– Analysis of achived condition levels on airports and runways

– Comparison of friction testers to each other

– RWYCC versus friction coefficient ratio

– Data exports

– Possibility to create customized analysis tools and add them as GRR-web modules

We have found some things in the new regulations that needs clarification. One of these issues is the above mentioned takeoff significant contaminant. Besides that, one big change in the reporting is the lack of friction coefficient in the RCAM table. The Runway Condition Code is mostly based on visual observation of the runway. This could lead to problems if there is no objective help to support the decision making.

We understand the difficulty of using friction testers for generating the RWYCC if there is no harmonization between different friction testers. But we among of a big majority of airports think that with correct usage of friction tester it´s a great advantage to combine the visual inspection and support the decision making with supporting tools such as friction tester and contaminant sensor. When there is enough knowledge, data and training, the supporting tools gives great advantage for safe runway reporting.

Besides friction tester we can utilize contaminant sensors. These sensors reads the contaminant type from the surface and also water depth. Supported contaminant types are water, snow, dry, slush and more. Combining this data with visual inspection, we can support and improve the inspector reporting accuracy.

Let us help you with your runway reporting needs and make it compliant to new Global Runway Reporting format. Please contact us and let´s book free visit where we train the new regulation changes and introduce our software solution.